How much influence do cutting parameters have on the efficiency of a metal band saw?

How do the parameters of band saw linear speed, feed speed, cutting fluid concentration, and average load per tooth affect cutting?

Metal band saw belt speed

The belt speed of a metal band saw determines how fast the metal band saw blade passes through the workpiece being cut (generally expressed in m/min). The higher the belt speed, the larger the shear angle, making it easier to separate the chips from the workpiece body with smaller shear force. However, the belt speed is affected by the processing performance of the material. If the tooth tip temperature is too high due to high speed, the tooth tip will wear quickly, thus affecting the life of the metal band saw. In addition, if the cutting force required for the material is large, too high a speed can easily lead to skewing.

So how do we determine that the linear speed of the metal band saw is normal?

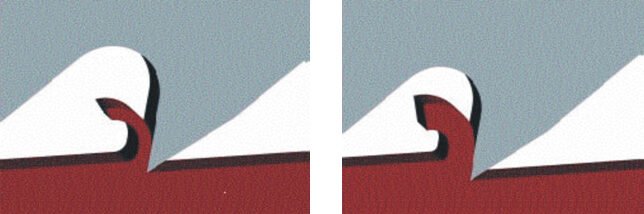

A rough tip is to check the shape and color of the chips. Normal chips should be thin, rolled but not hot, and shiny in color. If the chip color turns blue or black, the linear speed may be too high (for accurate measurement of linear speed, a linear speed measuring instrument can be purchased).

Metal band saw blade feed speed

The feed speed is the speed at which the tool cuts into the material (the falling speed of the metal band saw blade when cutting on the workpiece, generally expressed in mm/min). In order to control production costs, we need to increase the feed speed as much as possible. Feed speed is then limited by material processing properties and saw blade life. The higher the feed speed, the smaller the shear angle. Although a lower feed speed will increase the shear angle, it will also prolong the sawing time. Too fast a feed speed will also cause a significant reduction in the life of the saw blade. How to determine whether the feed speed is appropriate can still be judged by the chip shape. Please refer to the sawing speed column for how to judge chips.

Cutting fluid concentration and dosage suitable for metal band saws

The correct use of cutting fluid is also very important to extend the life of the metal band saw and reduce cutting costs. If cutting fluid is applied correctly, it can reduce the thermal stress in the tool and allow the chips to form a better chip flow on the rake face. If the cooling or lubrication is insufficient, the tool will undergo higher heat due to the friction between the chips and the various surfaces of the tool, and may form built-up edge on the cutting edge. Ultimately, this situation will lead to a reduction in tool life and may cause energy consumption to decrease. The increase causes the tooth tip to pull. Please use cutting fluid correctly according to the cutting fluid manufacturer’s recommendations, and keep a certain amount of cutting fluid in good proportion. Do not add water directly to the metal band saw when the cutting fluid is insufficient, because it will dilute the cutting fluid and cause changes in cutting conditions and may cause early dulling of the tooth tips. When the equipment is running, check whether all parts and parts that require cooling and lubrication are cooled and lubricated by the cutting fluid. And check the cutting fluid concentration frequently.

The concept of average load per tooth

The load per tooth is the average depth of penetration of each tooth of the metal band saw blade when it cuts into the material. This value is affected by the linear speed and feed rate (the cutting fluid concentration will affect the actual dispersion of this value).

Calculation formula of load per tooth:

Average load per tooth Fz=H/(40*V*t*TPI)

Fz: Load per tooth (mm)

H: Maximum cutting height of metal band saw (mm),

V: metal band Saw blade speed (m/min)

t: The total time it takes to process this piece of material (min)

TPI: Tooth pitch, if it is 3/4 teeth, it is 3.5

Things to note when using this formula:

Tooth Pitches = TPI, how many teeth per inch, which is the unit of tooth pitch we usually use.

The maximum material diameter determines the pitch selected for the material.

If several layers of materials are stacked together for sawing, then the final height of the stacked materials needs to be calculated.

In summary

In short, if the feed speed, cutting fluid concentration, and linear speed of the metal band saw are appropriate, the chips will be smoothly discharged after being rolled up after the tooth tip leaves the workpiece; if the feed speed, cutting fluid concentration, and linear speed are not appropriate, then The chips are very likely to stick to the tooth grooves and prevent smooth chip removal, which will affect the cutting of the next cut and even many subsequent cuts.