the leading band saw manufacturer

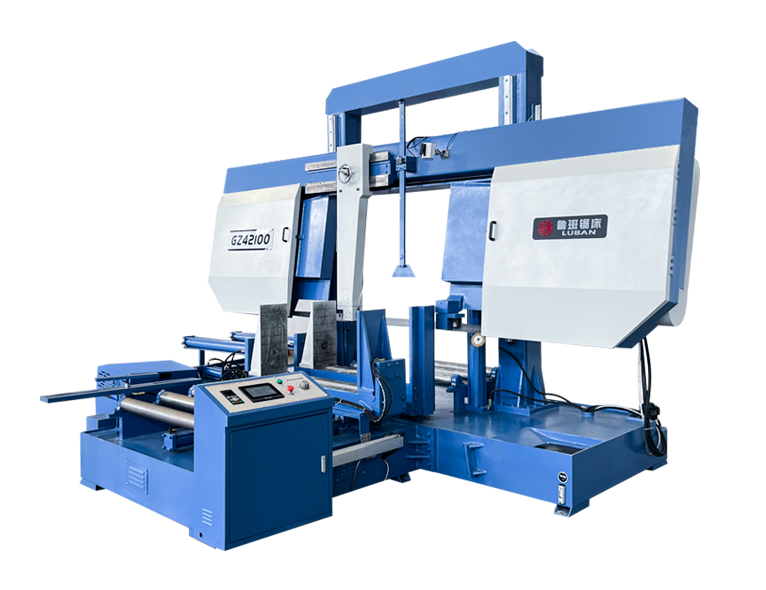

Metal Band Saw Machine

LUBAN has international quality management system, access to TUV, SGS, CE, ISO 9001: 2008. Our products have been sold worldwide for a wide range of applications in aerospace industry, Shipping industry, Automobile industry, Machinery manufacturing industry, steel industry, etc.

Hotsale Metal Band Saws Just in LUBAN - The Ultimate Solutions

Precision, Speed, And Cost-Efficiency

LUBAN is one of the

best metal band saws manufacturers & suppliers

in China since 1982. As a China-based

band saw factory

with over 20 years TUV certification, we offer wide range metal band saws like automatic band saws, semi-automatic band saws, heavy duty band saws, large band saws, horizontal band saws, miter band saws, double column band saws and metal band saw blades etc. Our company can offer customized band saws service according to your requirement too. Welcome to contact us for more information or request a fully product categolue.

Want your own band saw? Look no further! LUBAN is your one-stop-shop for everything band saw machine. We are a bandsaw-based company that takes pride in our superior cu.stomer service, sending you the best bandsaw products to your workshop. Click the button below to find what you’re looking for.

Circular cutting: ●600mm

Square cutting: ■600×600mm

Circular cutting: ●700mm

Square cutting: ■700×700mm

Circular cutting: ●800mm

Square cutting: ■800×800mm

Circular cutting: ●1000mm

Square cutting: ■1000×1000mm

Circular cutting: ●600mm

Square cutting: ■600×600mm

Circular cutting: ●700mm

Square cutting: ■700×700mm

Circular cutting: ●800mm

Square cutting: ■800×800mm

Circular cutting: ●1000mm

Square cutting: ■1000×1000mm

REQUEST A QUOTE FOR MORE DETAILS

All You Need to Know About Metal Band Saws

Metal band saw is the main equipment for cutting metal materials. Widely used in industrial production.

Due to the wide cutting range, good structural rigidity, high cutting accuracy, high efficiency and low cost of this band saw, industries that require metal cutting must use them. Additionally, many industries prefer this band saw because of its stable performance and ease of operation and maintenance. Metal band saws can operate semi-automatically and fully automatically.

This article gives you everything you need to know about metal band saws. What you will learn include what a metal band saw is used for, its components, how it works, and the different classifications of metal band saws. Later, you can look at the differences between double-column metal band saws, single-column metal band saws, and scissor-type metal band saws.

What Are Metal band saws Used For?

Metal band saws are present in almost all industries that need metal cutting. These could be the following:

- Aerospace Industry

- Shipping Industry

- Automobile Industry

- Machinery Manufacturing Industry

- Steel Industry

- Customized

How Does a Metal band saw Work?

Metal band saws are mainly used for cutting metal materials. After operating the electronic console, the band saw will run according to the instructions.

The cutting steps of a metal band saw are simple and easy to understand: power connection, electronic control instructions, feeding, clamping, and cutting.

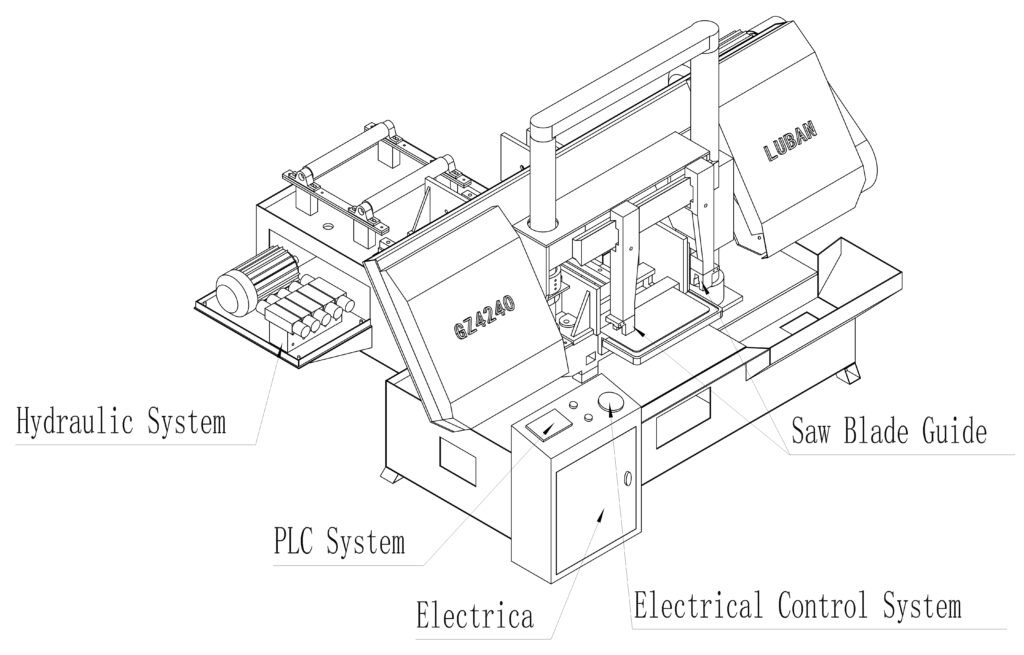

Metal band saw Parts

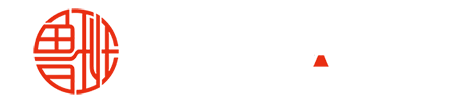

Metal band saws have very similar parts and features. While there are some differences, the main components and their uses are virtually the same. There are seven main parts to a metal band saw. Every component has been designed to a first-class level.

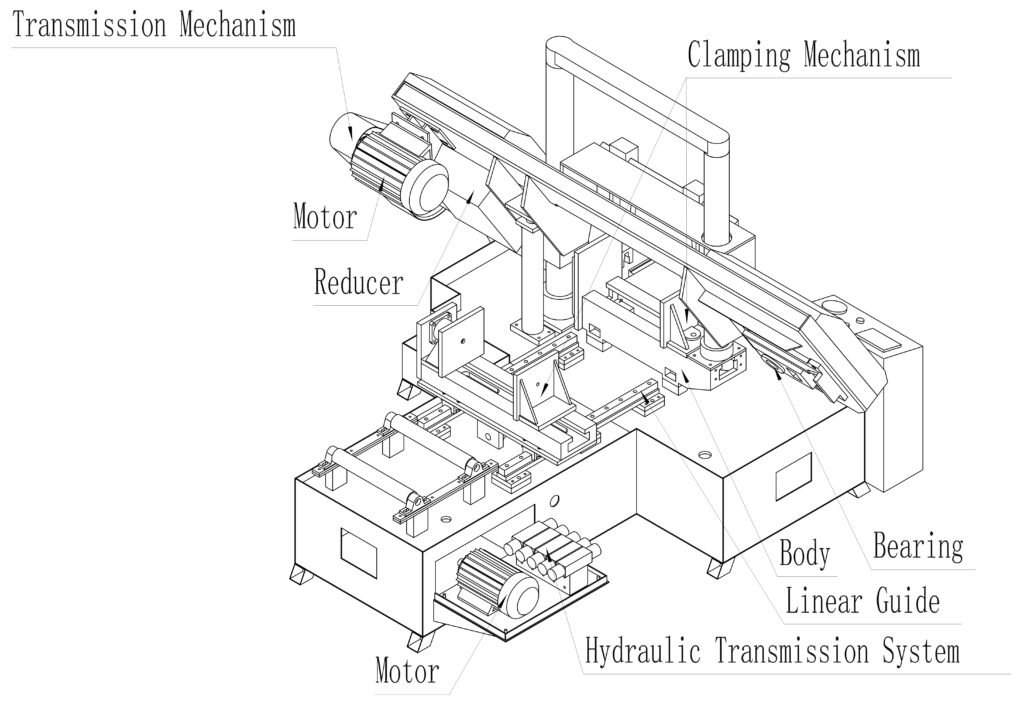

Body

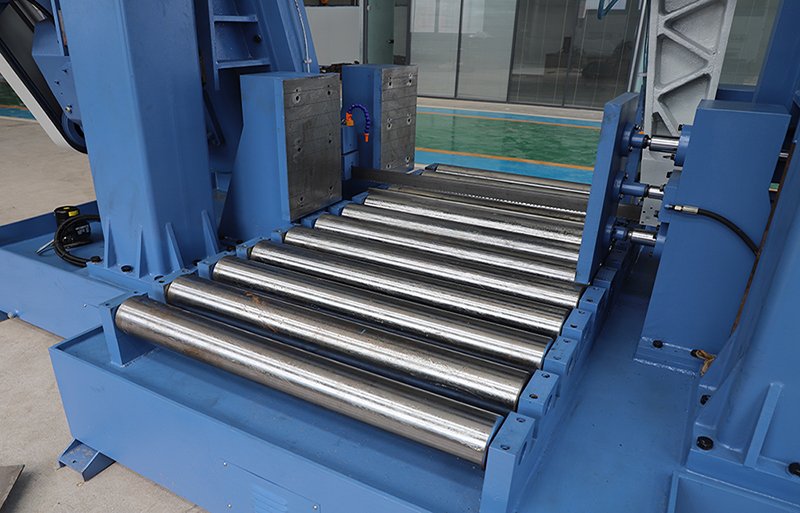

The bed of the metal band saw is made of cast iron and is fixed on the base. The upright column is composed of two columns. The two columns serve as guide rails for the saw frame to support the up and down movement of the saw beam and ensure accurate guidance to ensure the stability of the saw blade. Normal cutting. In the middle is a clamping vise and a feeding table. In front of the vise is a workbench for receiving finished parts.

Band saw blade guide

The guide device is installed on the saw beam support plate of the metal band saw. It consists of left and right guide arms and guide heads. Both the left and right guide arms can move along the dovetail. The guide device is used to change the installation angle of the saw blade so that the saw blade is perpendicular to the workbench.

Electrical control system

The electrical system of the metal band saw consists of a control loop composed of an electrical box, a control box, a junction box, a travel switch, etc., which is used to control the rotation of the saw blade, the lifting and lowering of the saw beam, the clamping of the workpiece, etc., so that it can operate according to certain working procedures.

Transmission mechanism

The rotary motion of the metal band saw blade is driven by the main motor, pulley, and worm gear on the back of the metal band saw through a two-stage variable speed transmission to the driving wheel, and then the driving wheel and the band saw blade drive the passive wheel. The band saw blade operates at a total speed of Third gear.

Clamping mechanism

The right vise is fixed on the bed of the metal band saw. The clamping screw rod passes through the inner hole of the hydraulic clamping cylinder. The left vise is connected by the screw rod and moves left and right along the guide rail. Press the clamping or unclamping button on the control panel to clamp or loosen the workpiece.

Hydraulic transmission system

The hydraulic transmission system of a metal band saw is a hydraulic circuit composed of pumps, valves, cylinders, fuel tanks, pipelines and other components. It completes the lifting and lowering of the saw beam and the clamping of the workpiece under electrical control. Through the speed regulating valve, the feed speed can be adjusted steplessly to meet the cutting needs of workpieces made of different materials.

Considerations When Buying Metal band saws

There are times when band saws do not perform at their optimum rate even if it is relatively brand new. Why is this so?

The answer lies in the knowledge and application of these band saws. Understanding these considerations are part of lengthening the life of such band saws.

Standard

Selecting the optimal Metal band saw is crucial as it influences cutting precision. Matching the Metal band saw type with material characteristics ensures accurate and effective cutting, while an incorrect match could lead to subpar results.

Design

The construction of a Metal band saw reflects its rigidity and the manufacturing prowess behind it. From R&D to end-user experience, the structure of the Metal band saw is pivotal in defining its overall performance.

Power

Considering the drive is essential when throughput is a priority. Heavy-duty cutting necessitates a robust Metal band saw, whereas lighter materials can be handled by smaller variants. Selection should align with the Metal band saw specifications and material dimensions.

Material

The durability and operational stability of a Metal band saw hinge on the quality of its material. Superior materials extend the lifespan, whereas inferior quality can lead to a decrease in the Metal band saw’s efficiency.

Efficiency

Efficiency seekers must scrutinize the Metal band saw’s componentry. The synergy between core components such as electrical and hydraulic systems, PLCs, motors, and reducers significantly dictates the Metal band saw’s material cutting efficiency.

With this in mind, it is important that band saws adhere to production standards and strict regulations implemented by international agencies. This ensures safe use and meeting cutting requirements for band saw users.

Metal band saw Types By Body Design

The two common body designs for metal band saws are horizontal and vertical type.

These refer to the mounting schemes generally used by metal band saw manufacturers.

Horizontal metal band saw has a double-column structure, which consists of a transmission system, an electrical system, a band saw blade guide device, a guide arm locking device, a front and rear motorized roller feeding device, an automatic stop device for broken or stuck belts, and an electrical box door-opening power-off device, and hydraulic system. The horizontal band saw is mainly used for sawing round materials, square materials, profiles and pipes of ferrous and non-ferrous metal materials. It can cut carbon steel, alloy steel and bearing steel. It is suitable for sawing large forgings, steel ingots and mold blanks. Suitable for single piece and batch production in various industries.

Vertical Metal band saw

Vertical metal band saw is a pulley vertical structure, which is composed of saw frame, workbench, transmission system, saw frame drive system, band saw blade guide device, hydraulic system, electrical system, cooling system, lifting feeding device and chip removal device. Vertical metal band saws are mainly used for sawing large ferrous metal plates and mold blanks, and are suitable for single-piece and mass production in mechanical processing plants.

Metal band saw Types By Structure Design

A Horizontal metal band saw is the most widely used band saw machine for material cutting, and it occupies the first of the band saw machine rankings. When it’s time to choose a metal band saw machine, think beyond size and price. For cutting, machine design impacts your workflow and product quality. You need to understand their limits for the best investment.

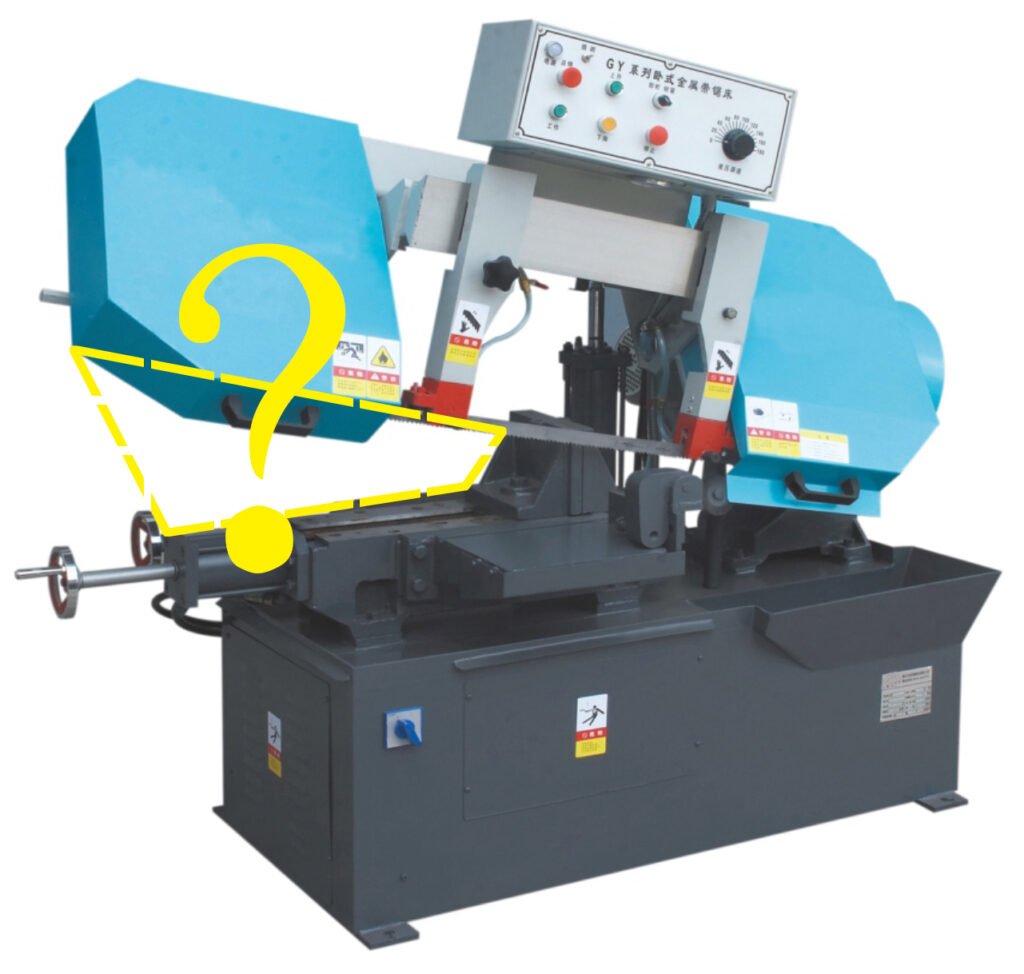

Single-Column metal band saw

Its may be a budget-friendly pick, but with challenging materials, it can wobble, affecting cut accuracy. If your projects involve heavy or thick metals, this could mean more waste and redoing work, hitting your efficiency hard.

Scissor-Type metal band saw

It offer simplicity, yet the single pivot design struggles with consistency over time. This leads to more blade wear and potential inaccuracies, a costly downside when precision is your top priority.

In the long run, a double column metal band saw is a wise choice. It’s an investment in fewer interruptions, steady cutting, and reliable outcomes. It’s not just about what the machine does, but how it keeps your operations sharp, predictable, and cost-effective.

Metal band saw Types By Operate Design

Deciding between an automatic and semi-automatic metal band saw machine hinges on production needs and operational scale. Choose an automatic metal band saw for large-scale, repetitive tasks where uniformity and volume are paramount. In contrast, a semi-automatic metal band saw is ideal for smaller batches or specialized cuts. Your selection directly impacts productivity and cost-effectiveness, making it crucial to align machine capabilities with business objectives.

Automatic metal band saws are also named CNC band saws. It embodies the highest level of metal band saw technology development and realizes fully automatic cutting functions of repeated automatic measurement, automatic feeding, automatic cutting, and automatic standby after completion. In addition, the cutting accuracy of the fully automatic metal band saw is also the highest. After rigorous calculations, the output of a fully automatic metal band saw is equivalent to the output of four traditional sawing machines, and saves 3 manpower. The fully automatic metal band saw is the first choice for batch cutting and efficient and high-precision cutting.

Semi-automatic metal band saw is a band saw that is commonly used for cutting metal materials. Its operation method is to manually operate the button to run the metal band saw. For example, the start or stop of the band saw, the lifting and lowering of the saw beam and the speed, the start of the hydraulic system, the operation and speed of the band saw blade, and the clamping or loosening of the hydraulic vise are all operated by buttons. In addition, measuring the cutting length also requires manual operation. Compared with the original manual band saw, the semi-automatic metal band saw liberates manpower to a certain extent. The operator does not need to directly participate in each action, but only needs to operate the buttons to complete the cutting.

Metal band saw Types By Feed Design

Automatic feeding is one of the features of the fully automatic metal band saw. The feeding system of the metal band saw operates according to the instructions of the PLC system. No operator involvement is required.

Electric feed is used in traditional metal band saw cutting operations. If you have a semi-automatic metal band saw or a manual metal band saw and want to give up manual pushing of materials, you can choose an electric feed frame. It is connected to the electronic control system of the metal band saw and completes electric feeding on the electrical operating console. More importantly, it can reduce the operator’s labor intensity and improve safety.

The manual feeding method means that when operating a semi-automatic metal band saw or a manual metal band saw, the material needs to be manually pushed to the cutting position of the metal band saw. If it is a lightweight material, it is less labor intensive. If it is heavy and large materials, the labor intensity will be very high.

Metal band saw Types By Craftsmanship Design

A 90-degree cut is a common process for metal band saws, also known as a 0-degree cut or a right-angle cut. It is generally used to cut long materials into various short materials.

Before diagonal welding of metal materials such as profiles, 45 Degrees cutting is usually performed with Mitering cutting metal band saw. The cutting surface must be kept at a precise angle, clean and flat before it can be used in the butt welding process.

Metal Band Saw Types By Scenes Design

In industrial production and manufacturing, metal material cutting is the first process. This shows the status of metal band saws in the manufacturing industry. With the continuous development and needs of world industry, the technological innovation and breakthroughs of metal band saws are changing with each passing day.

Household metal band saws are small or mini band saws. It can cut light or micro materials by hand and is a band saw tool for home repair.

Metal Band Saw Types By Effect Design

Large metal band saws are used for cutting heavy and large metal materials. Such heavy materials are usually large in volume and weight, and have high requirements on the structure, load-bearing and cutting capabilities of the metal band saw. Large metal band saws feature high rigidity, high stability, high precision and durability.

Small metal band saws are used for cutting small and medium-sized metal materials, such as bars, profiles, H-beams, and pipes, etc. This type of material is characterized by small port area and light weight. Metal band saws can be selected based on the operator’s needs, cutting output, and cutting data.

Request A Free Quote

We'd Like To Work With You

Send us a message if you have any questions or request a quote.

Our experts will give you a reply within 24 hours and help you select the right band saw machine you want.

- +86 182 6527 8599

- +86 182 6527 8599

- luban@lubansaws.com